We are one the best digital fabric printers in the industry. Depending on the process, there are various steps that need to take place in order to ensure a quality and dependable print:

|

|

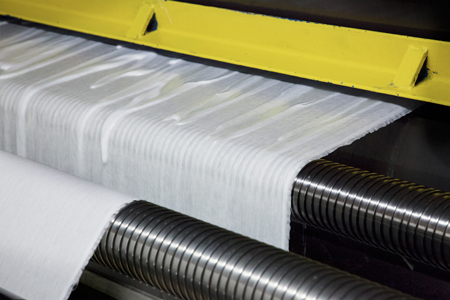

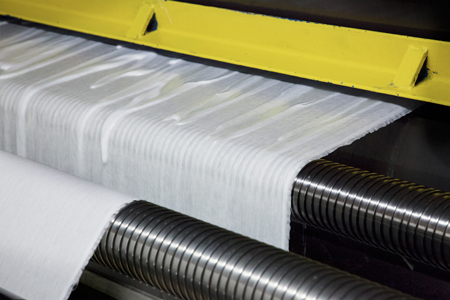

1. Pre Treatment -

If the fabric is to be printed using a Direct Print Process, a treatment is applied to the Fabric, to optimize Color and Performance.

|

|

|

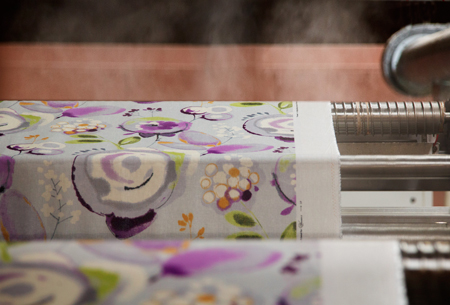

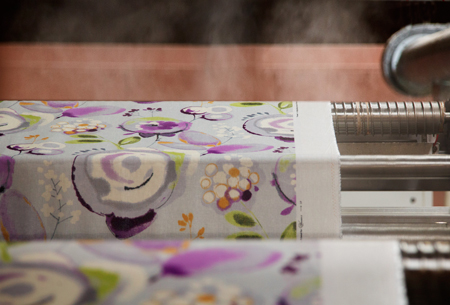

2. Printing -

Print is applied directly to the fabric with the proper inkset for the chosen substrate. For the instance of Dye Sublimation, a mirror image is applied to a specially coated paper for future transfer to fabric.

|

|

|

3. Fixation -

Different inksets require different environments to ensure a proper fixation to the fabrics. Some will require Steam, some will require Dry Heat, and Some both Pressure and Heat. |

|

|

4. Post Treatments -

Have a special application need? No problem! Advanced Digital Textiles can treat your fabric with a variety of in-house options:

- Water Repellents

- UV Inhibitors

- Softeners

|

- Anti-Microbials

- Stain Prevention

|

|

|